Kwik-Way SVS-II Deluxe HP Valve Refacer

Kwik-Way SVS II Deluxe

The best engine valve refacer on the market

- Kwik-Way's precision 6-ball chuck for fast, accurate centering of your valves - no collets to change'

- Standard 4mm to 14.3mm chuck capacity

- Variable speed chuck to match the proper speed needed to grind today's variety of valve materials

- Rocker arm grinding attachment included

- .0005 accuracy for standard chuck

- .0002 accuracy for high performance chuck

- Industry's Best - Back by our exclusive 3-year warranty

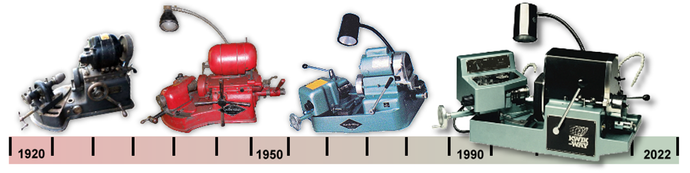

Manufactured in the United States by Irontite Inc. since the early 1920’s

Ever since the need for a valve refacer first became apparent, we have been in the forefront of making and improving the best machine for the job.

Features of Kwik-Way SVS II Deluxe Valve Refacer

Solid Cast Iron Construction

Poured in the USA and machined in Cedar Rapids, Iowa, the 2 solid cast iron blocks that make up the Kwik-Way SVS II Deluxe give strength and stability to the whole structure.

The weight of a solid cast iron base absorbs vibrations, dampens harmonics, eliminates chatter, and maintains accuracy for a very long service life.

Large Valve Capacity

The SVS II Deluxe Double Dovetail Slideway and micrometer feed system allow large valves up to 15” (385mm) long to be easily set up and ground.

Exclusive Six-ball Chuck Design

Every Kwik-Way chuck features two sets of 3 balls each that grip the valve stem on that part which travels in the valve guide. This patented design ensures perfect concentricity between the stem and the valve head and provides precision and reliability.

The compound compensating, self-centering, six-ball chuck automatically aligns the valve, refacing it concentric with the original centerline of the valve system. This type of 2-point stem support is referred to as a “Centerless” grinding system.

The valve is kept firmly in place by pneumatic action, controlled either by a lock/release button or a convenient pedal. Pneumatic operated change-over also eliminates the need to switch off the motors when changing valves, reducing machining time and increasing life of motors.

The 6-ball chuck supports variable valve rotation speed, which allows the operator to adjust surface speed and ensure the best surface finish for a wide range of valve head diameters. The standard chuck supports valve stems between ø 4 and 14mm, and an optional chuck is available for larger diameters ranging from ø 11 to 21mm. Other valve grinding machines can require up to 9 separate collets to achieve the same range.

The chuck itself is mounted on the head, which can then be inclined up to 62°.

Grinding Wheels

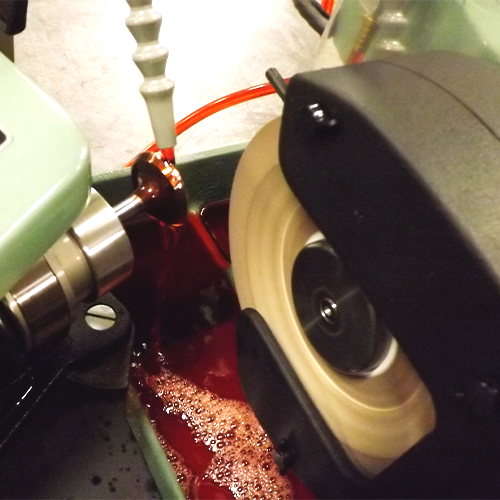

The Kwik-Way SVS II Deluxe centerless valve refacer is equipped standard with a 7” (178mm) vitrified grinding wheel, additional 3” (76mm) wheel, along with grinding oil and a diamond dresser. The retractable main wheel diamond dresser is set to the exact position of the wheel face to dress or re-sharpen the wheel as needed.

Kwik-Way’s separate, belt-driven spindle isolates any motor vibration or harmonics to provide a smooth “chatter free” finish and a wide variety of special wheels for grinding difficult metals, such as titanium or Inconel, are also available.

The Kwik-Way SVS II Deluxe is equipped with a 1 gallon (3.8L) tank for the coolant. Optionally, an external 5 gallon (18.9L) large capacity coolant tank is available. The larger tank can greatly extend the time between oil changes and fits perfectly into the optional base storage cabinet but can also be easily retrofitted to any SVS II Deluxe Valve Refacing Machine.

How to reface an engine valve with Kwik-Way’s SVS II Deluxe

Using the Kwik-Way SVS II Deluxe automotive valve grinder is a straightforward process and a deluxe control panel places important features at your fingertips - valve counter, chuck speed control, separate switch positions for spindle and chuck motors, valve speed chart, and machine maintenance chart.

- First set the machining angle for your valve and adjust the grind valve stem end to square to the valve centerline. The V rest allows all valves in a set be ground the same distance from valve seat to stem end - essential for overhead camshaft type cylinder heads.

- Set the rotation speed for the valve and grinding wheel and trigger the lever to turn on the motors and the coolant pump.

- As the grinding wheel approaches the valve it will automatically start rotation, and then automatically shuts off as it moves away.

- Pushing the pneumatic actuation button will stop the valve rotation motor and release the rectified valve. Rotation returns immediately when the button is released, which not only makes for safe operation of the machine, but also enables the operator to move through a set of valves very quickly.

- A valve stop eliminates the need to reset for the next valve. Simply pop the next valve in and it lines up perfectly for the grinding operation. A precision threaded feed that is protected from dirt and grime, accurately controls valve travel into and away from the grinding wheel surface.

Specifications

| Minimum Chuck Capacity (Standard / High Perf) | .157” (4.0 mm) |

| Maximum Chuck Capacity (Standard / High Perf) | .5625” (14.3 mm) (up tp 21mm w/ optional chuck) |

| Valve Head Diameter Capacity | .750” – 4” (19.015 - 101.6 mm) |

| Minimum Valve Stem Length | 1.900” (49mm) |

| Minimum Total Valve Length | 3.375” (85.73 mm) |

| Valve Wheel Diameter | 7” (178 mm) |

| Surface Wheel Diameter | 3” (76 mm) |

| Spindle Drive Motor | ½ HP |

| Chuck Drive Motor | Gear Drive 1/12 HP |

| Coolant Capacity | 1 Gallon (3.8L) |

| Valve Wheel RPM/SFPM | 3450 RPM / 6322 SFPM |

| Stem Sheel RPM/SFPM | 3450 RPM / 2708 SFPM |

| Chuck Speed | Variable Speed: 100 – 300 RPM |

| Minimum Air Requirement | 65 PSI |

| Overall Length | 37” (940 mm) |

| Overall Width | 22” (599 mm) |

| Overall Height | 16” (406 mm) |

| Height on (optional) Cabinet | 51” (1295 mm) |

| Shipping Weight | 330 lbs. (150 kg) |

| Model # | Part # |

|---|---|

| SVS II DELUXE - 115v/60Hz/1Ph | 012-005-00 |

| SVS II DELUXE - 115v/60Hz/1Ph w/ High Performance Chuck | 012-0005-01 |

| SVS II DELUXE - 115v/60Hz/1Ph w/ 7/16 - 13/16” (11.1 - 21mm) capacity chuck | 012-0005-10 |

| SVS II DELUXE - 230v/50Hz/1Ph | 012-0005-20 |

| SVS II DELUXE - 230v/50Hz/1Phw/ High Performance Chuck | 012-0005-03 |

Refacer Accessories

| Standard Accessories | Part # |

|---|---|

| 1 Gallon (3.8L) Grinding Oil | 000-2112-73 |

| Chuck Assembly Tool | 012-1054-60 |

| Spanner Wrench | 025-0150-02 |

| Diamond Dressing Tool – Tip Grinding | 024-0131-11 |

| Diamond Dressing Tool – Face Grinding | 023-0129-44 |

| Rocker Arm Attachment Assembly | 012-1120-00 |

| Optional Accessories | Part # |

|---|---|

| Valve Refacer Cabinet | 012-0039-00 |

| High Performance Chuck (.0002 or less) .157” - .5625” range (4.0 – 143. mm) | 012-1575-84 |

| 21 mm Chuck 7/16” 13/16” rang (11.11 – 20.6 mm)(*requires 012-1033-21 yoke) | 012-1025-21 |

| External Pump & 5 gal. Oil Tank | 012-2111-50 |

| Foot Pedal Activated Chuck (only when ordered with machine) | 012-0400-00 |

| Small Collet Chuck Kit (3 to 6 mm) | 012-1575-60 |