Comec ACF200 CNC Cylinder Boring Resurfacing Machine

The ACF200.CNC boring machine combines the two main operations of reconditioning the monoblocks of cars and trucks, such as boring and smoothing, in a single machine and now completely automatically thanks to CNC control.

The finest finishing and precision qualities that characterize it are the result of a combination of a proven mechanical design and the introduction of highly innovative technology solutions that make it smart even faster and more practical to use.

Browse other cylinder boring machines.

Standard equipment

| Including standard equipment as follows: |

| MNF200 Single phase version (220V/60Hz/1ph) |

| Computer Numerical Control - LINUX Operating System and ARMv8 CPU Processor |

| Precision Ball screw drives on 3 Axis |

| Movements by linear railways on 3 Axis |

| Brushless motors on 3 Axis controlled by CNC |

| Swing arm control panel with double touch screens |

| Electronic Handwheel on 3 Axis (Fast-Medium-Fine modes) |

| Automatic and programmable working modes for boring and milling operations |

| WI-FI and LAN connections for support and service |

| SSR200 Spindle Storage Rack |

| C06085-P Dia. 2.362”÷3.346” (60÷85 mm) boring spindle with accessories |

| C85170-P Dia.3.346”÷6.693” (85÷170 mm) boring spindle with accessories |

| PF0350 Dia.14” Milling plate |

| UT1330 1/2” CBN/PCD Toolholder |

| UT1355 1/2" CBN insert for cast iron |

| PV0160 pair of parallel supports |

| PV0021 large clamps (2 pcs.) |

| PV0022 small clamps (4 pcs.) |

| Wrench set |

| Instruction manual |

Specifications

| Boring range | 1.4"- 6.7" / 35÷170 mm |

| Max head vertical travel | 27.6" / 700 mm |

| Min-Max distance from head to table | 14.6" - 40.2" / 370÷1020 mm |

| Distance between spindle C/L and column | 11.4" / 290 mm |

| Table surface | 52.8" x 14.6" / 1340x370 mm |

| Max table longitudinal travel | 47.2" / 1200 mm |

| Max table transverse travel | 7.9" / 200 mm |

| Adjustable spindle rotation speed | 75÷850 rpm |

| Adjustable boring bar feed | 0÷3000 mm/min. |

| Adjustable table feed | 0÷3000 mm/min. |

| Spindle motor power | 1.5 kW |

| Rapid feed motor power | 1.27 N/m |

| Table and travers feed motor power | 1.27 N/m |

| Dimensions (LxWxH) | 81"x 49" x 86" / 2045 x 1245 x 2175 mm |

| Weight | 3,395 lbs. / 1540 Kg |

Power Requirements: 220 Volt/ 1 Phase/ Full Load AMPS: 15A

Shipping information: 90.6" x 50.4" x 93.7"

Shipping weight: 3,915 lbs.

Accessories and Spare Parts

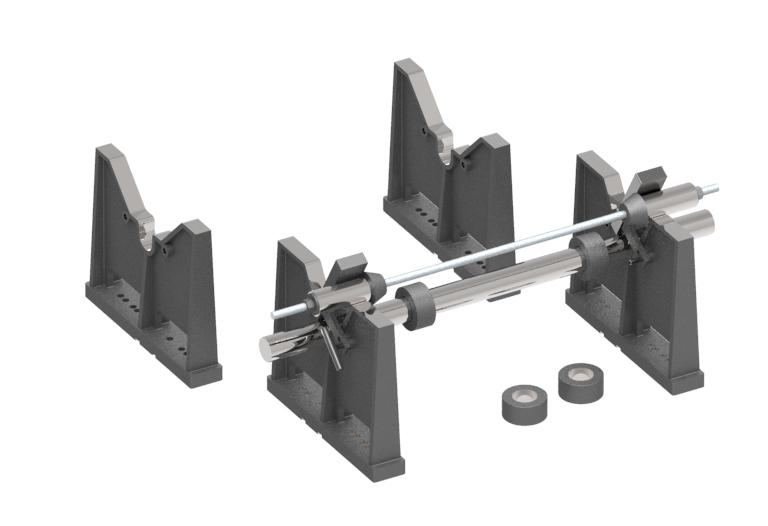

PV1516

60° – 90° V-block blueprinting mounting fixture

PV0025

Pair of fast clamping column

PV0160

Pair of parallel supports

UT1390

ALP insert tool holder for UT1392

UT1392

ALP insert for aluminum with prechambers

UT1320

3/8” CBN/PCD insert tool holder

B03560

Ø 35÷60 mm L = 330 mm boring kit with dial gauge adjustment

B06085

Ø 60÷85 mm L = 320 mm boring kit with dial gauge adjustment

C03560

Ø 35÷60 mm L = 330 mm boring kit with pre-setting system

C06085

Ø 60÷85 mm L = 320 mm boring kit with pre-setting system

C85170

Ø 85÷170 mm L= 360 mm boring kit with pre-setting system

B85170

Ø 85÷170 mm L = 360 mm boring kit dial gauge adjustment

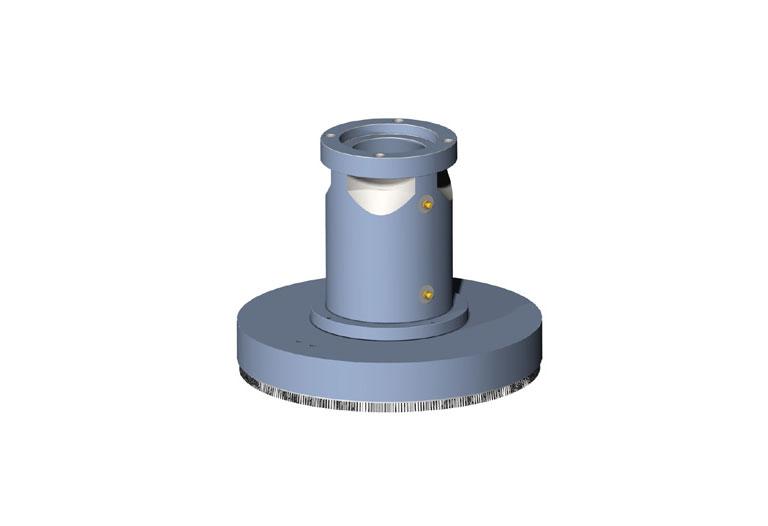

PF0320

1/2” CBN or PCD milling plate dia. 320 mm (available only for ACF)

UT1330

1/2”CBN/PCD insert tool holder

UT1345

3/8” CBN Insert for cast iron

UT1346

3/8” PCD Insert for aluminium

SSR200

Spindle storage rack