Comec ACF200 Cylinder Boring Resurfacing Machine

This ACF200 machine includes both main recoditioning operations of light and heavy vehicles cylinder blocks: boring and resurfacing.

Despite its compact dimensions, the ACF200 ensures considerable work capacities, thanks to the wide longitudinal and transversal table feed and the vertical feed of the head.

The excellent qualities of precisiong and accurate finishing are the result of a combination of a well tested mechanical structure and innovative technical solutions, which improve the performance of the machine.

Consult the brochure, watch the video or contact us for any other inquiry.

DIFFERENCES BETWEEN SPINDLES KIND B AND C

Browse other cylinder boring machines.

Images may show the product equipped with optional accessories

BROCHURE

Standard equipment

| Including standard equipment as follows: |

| MNF200 Single phase version (220V/60Hz/1ph) |

| Variable spindle speed with digital display |

| Variable head feed speed |

| Head power feed |

| Ball screw drive on head and table |

| Boring depth device with dial gauge |

| Precision centering device with dial gauge |

| Adjustable stroke-end switches |

| Motorized traverse table with variable feed speed |

| C06085-P Dia. 2.362”÷3.346” (60÷85 mm) boring spindle with accessories |

| C85170-P Dia.3.346”÷6.693” (85÷170 mm) boring spindle with accessories |

| PF0350 Dia.14” Milling plate |

| UT1330 1/2” CBN/PCD Toolholder |

| UT1355 1/2" CBN insert for cast iron |

| TSTP10 Depth indicator complete of dial gauge |

| PV0160 Pair of parallel supports |

| Oil for slides (1 lt.) |

| Wrench set |

| Instruction manual |

Specifications

Boring range: 1.4"÷ 6.7" / 35÷170 mm

Max head vertical travel: 26.4" / 670 mm

Min-Max distance from head to table: 14.6"÷ 40.2" / 370 ÷1020 mm

Distance between spindle C/L and column: 11.4" / 290 mm

Table surface: 52.8" x 14.6" / 1340x370 mm

Max table longitudinal travel: 47.2" / 1200 mm

Max table transverse travel: 7.9" / 200 mm

Adjustable spindle rotation speed: 75 ÷ 850 rpm

Adjustable boring bar feed: 0÷175 mm/min.

Adjustable table feed: 0 ÷6.9" in/min / 0÷460 mm/min.

Spindle motor power: 2 Hp/ 1.5 kW

Rapid feed motor power: 0.5 Hp / 0.37 kW

Table feed motor power: 0.75Hp / 0.55 kW

Power Supply: 220V/60Hz/1Ph

Dimensions: (LxWxH) 73" x 45" x 86" /1860 x 1150 x 2170 mm

Weight: 3,042 lbs. / 1,380 Kg

Power Requirements: 220 Volt/ 1 Phase / Full Load AMPS: 13.6A

Shipping information: 81.9" x 48.4" x 88.2"

Shipping weight: 3,640 lbs / 1,651 kg

Accessories and spare parts

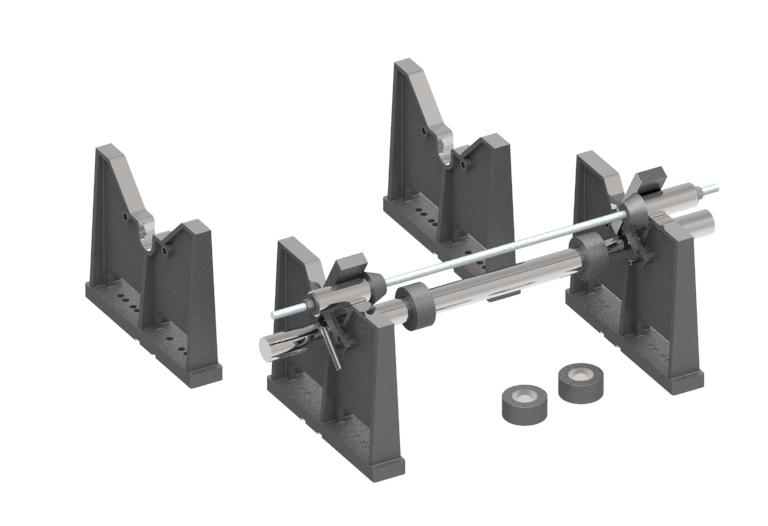

PV1516

PV1516 60°- 90° V-block blueprinting mounting fixture

PV0025

PV0025 Pair of fast clamping column

PV0007

PV0007 Pair of parallel supports H=1.9" / 49mm

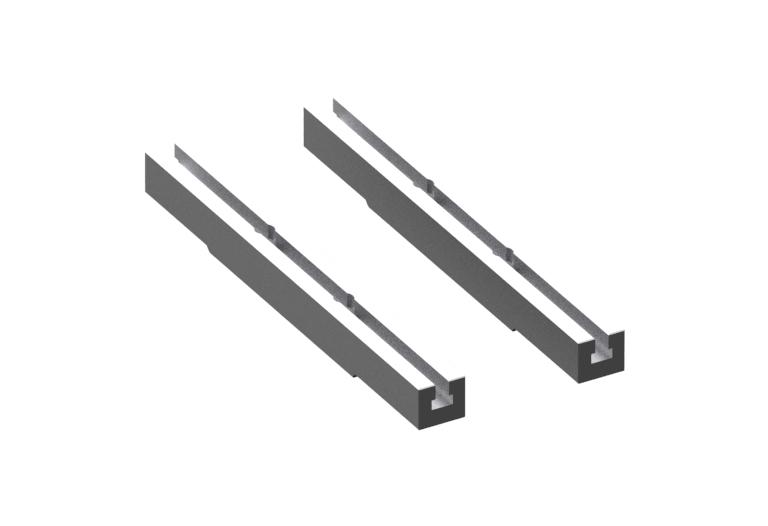

PV0160

PV0160 Pair of parallel supports

UT1320

3/8” CBN/PCD insert tool holder

UT1355

1/2” CBN Insert for cast iron

UT1356

1/2” PCD Insert for aluminium

B03560

1.37" - 2.362" / Ø 35÷60 mm / Lenth= 12.99" / 330 mm boring kit with dial gauge adjustment

B06085

2.362" - 3.346" / Ø 60÷85 mm L =12.99" / 320 mm boring kit with dial gauge adjustment

C03560

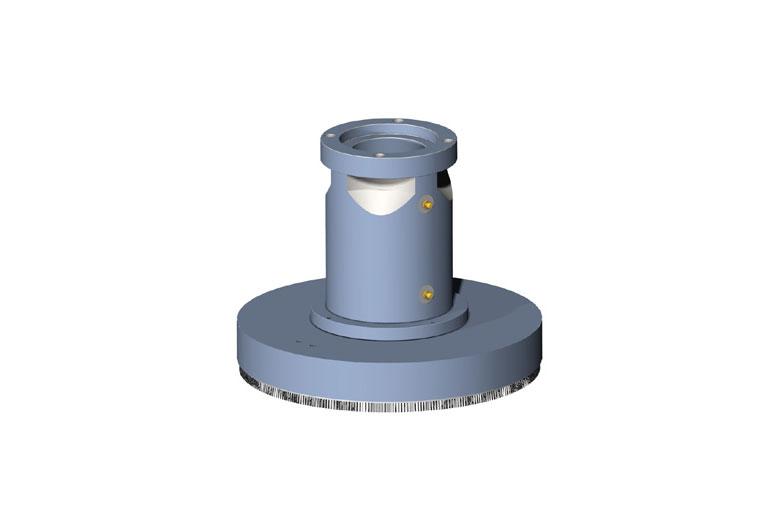

1.37" - 2.362" / Ø 35÷60 mm / Lenth= 12.99" / 330 mm boring kit with pre-setting system

C06085

2.362" - 3.346" / Ø 60÷85 mm L =12.59" / 320 mm boring kit with pre-setting system

C85170

3.346" -6.693" / Ø 85÷170 mm L= 14.17" /360 mm boring kit with pre-setting system

B85170

3.346" - 6.692" / Ø 85÷170 mm/ Length= 14.17" / 360 mm boring kit dial gauge adjustment

PF0320

1/2” CBN or PCD milling plate dia. 12.598" / 320 mm (available only for ACF)

UT1330

1/2”CBN/PCD insert tool holder

UT1345

3/8” CBN Insert for cast iron

UT1346

3/8” PCD Insert for aluminium

SSR200

Spindle storage rack

PVB015

V-block adjustable universal fixture