Comec RP1300.M Cylinder Head and Block Resurfacing Machine

The RP1300 is a resurfacing machine designed for cylinder heads and blocks of cars and trucks but also for all those flat surfaces that require an extremely precised side contact.

This model combines tested solutions, such as the flat and V-shaped lubricated slides on the base (which guarantee an excellent run fluidity), with other more innovative features, like the table feed through a recirculating-ball screw with a wide range of regulation or an inverter for the spindle speed regulation. Moreover, RP1300 has an efficient cooling system consisting in a tank on wheels and a grinding wheel dresser. For a convenient and safe use of the machine, all control commands are located on a swing arm control panel adaptable to every operator;

The standard version includes, a segmented grinding wheel for cast iron or aluminium and pre-chamber cylinder head resurfacing and brazed tool for aluminium machining.

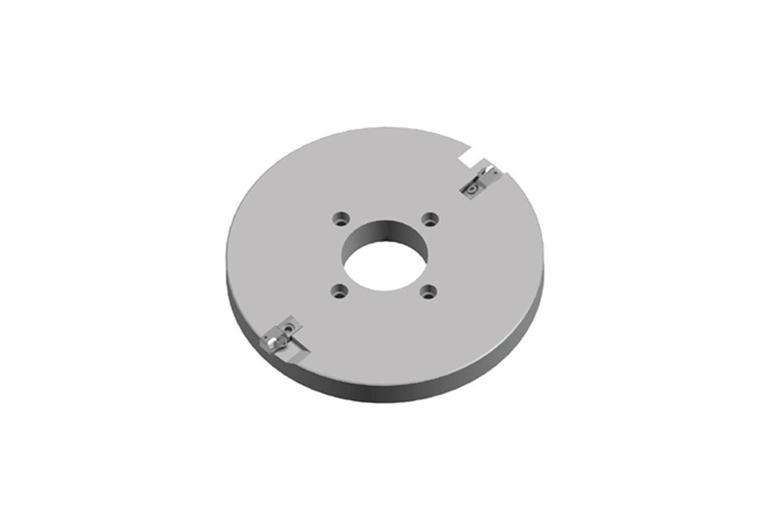

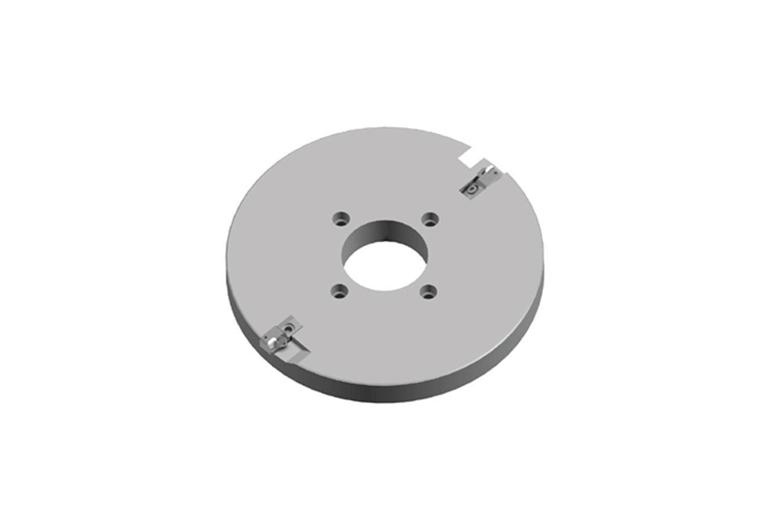

Available as optional a CBN-PCD toolholder plate for the reconditioning at high speed of cast iron and aliminium heads.

Consult the brochure or contact us for more information.

STANDARD EQUIPMENT

| MNF100 Single phase version (220V/60Hz/1ph) |

| Variable head spindle speed with digital read-out |

| Variable table travel feed |

| Ball screw drive feed on table |

| Head power feed |

| Manual/continuous/automatic working modes |

| Dia. 16” (405 mm) CBN-PCD Milling plate |

| UT1330 1/2” CBN/PCD Toolholder |

| UT1355 1/2" CBN insert for cast iron |

| UT1330 1/2” CBN/PCD Toolholder |

| UT1356 1/2” PCD Insert for aluminium |

| TSTP10 Depth indicator on sliding Railway (without dial gauge) |

| ACP092 Dia. 55 mm dial gauge (inches) |

| Swing arm control panel |

| Safety guard with policarbonate shield |

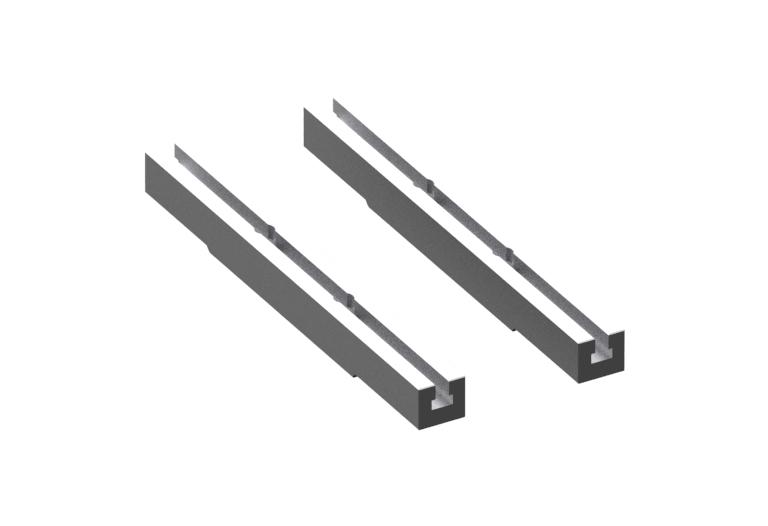

| PV0160 Pair of parallel supports |

| PV0021 Large clamps (2 pcs.) |

| PV0022 Small clamps (4 pcs.) |

| PV0015 Universal fixture for canted Cylinder Head |

| PV1515 V-Block mounting kit |

| Oil for slides (1 lt.) |

| Wrench set |

| Instruction manual |

| EC declaration of conformity |

SPECIFICATIONS

| • Table Traverse: 55.1" / 1400mm | |||||

| • Max. Working Length: 48.2" /1255mm | |||||

| • Max. Working Width: 16" /405mm | |||||

| • Max. Working Height: 7.5 ÷ 28 /190 ÷710mm | |||||

| • Useful Table Surface: 43.3"x 9.1"/1100x230mm | |||||

| • Milling Plate Diameter: 16" / 405mm | |||||

| • Spindle Rotation Feed: 300 ÷ 1200 | |||||

| • Variable Table Feed Speed: 0 ÷ 59 / 0 ÷ 1500 | |||||

| • Spindle Motor 3 hp/ 2.2kW | |||||

| • Table Motor: 1 hp /0.75kW | |||||

| • Rapid Feed Motor: 3 hp/ 2.2kW | |||||

| • Power Supply: 220v/60Hz/1ph |

Dimensions: (LxWxH): 87" x 51" x 79" /2200 x 1300 x 2000mm

Weight: 3,108 lbs. /1410kg

Accessories and Spare Parts

PVA015 Adjustable universal fixture wit parallels

PV0007 Pair of parallel supports H=49mm

PV0015 Adjustable universal fixture with mounting plate

PV0160 Pair of parallel supports

PL000A Motor driven rotary table

RP1361 CBN/PCD/ALP Milling plate dia. 355 mm (14”)

UT0018 Aluminum with Pre-chamber insert tool holder

UT0023 3/8” CBN/PCD insert tool holder

UT0017 Insert tool holder with UT0014

UT0014 Replacement insert for UT0017 (10 pcs)

UT1355 1/2” CBN Insert for cast iron

UT1356 1/2” PCD Insert for aluminium

UT0003 Head resurfacing tool

UT1330 1/2" Insert tool holder for UT1355 (CBN), UT1356 (PCD)

RP1364 Dimensions 410 mm (16”) 1/2” CBN or PCD milling plate

PSC130 Splash and safety guard with sliding doors

UT1320 3/8” CBN/PCD insert tool holder